Multi-stage centrifugal blowers are as well one of the most efficient and reliable blowers when it comes to industrial processes which demand the movement of air or gases which have to be of high pressure. These machines are popular in industries of wastewater treatment, power generation, petrochemical, cement, as well as food processing. We will discuss the reasons why multistage centrifugal blowers are unique, their main advantages, and why they continue to be a reliable option to be used in challenging applications.

What Are Multistage Centrifugal Blowers?

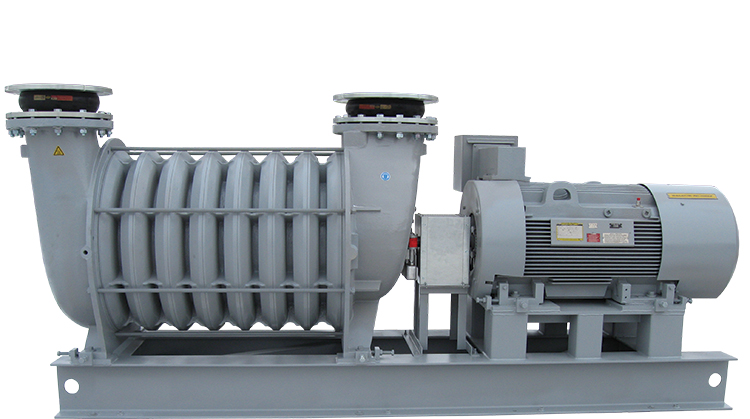

Multistage centrifugal blower A mechanical device which moves air or gas by accelerating it with a series of impellers. Different impellers enlarge the speed of the air and this speed is converted to the pressure. Due to the multiple stages of the blower, the high pressures can be generated much higher than in units with single stages. This is because they are best used in the applications where there should be a steady airflow at medium to high pressure levels.

Multistage Centrifugal Blower Advantages.

- High Efficiency: Multistage centrifugal blowers are made to reduce the amount of energy used without compromising on the level of airflow and pressure. They are effective and hence cost-effective in the long-term.

- Reliability: These blowers are designed to operate continuously which means that they have fewer moving parts than other technologies of the blower, which lowers the cost of wear and maintenance.

- Silent Operation: They have high engineering and balancing, which makes them less vibrational and produce less noise hence acceptable in indoor and sensitive environments.

- Adjustable Pressure and Flow: Multistage designs enable engineers to customize the stages to fit the requirements of a particular industry.

- Durability: They are made with the material that is very strong and can perform during the years of hard use.

Applications of Multistage Centrifugal Blowers

They are commonly used in the following applications.

- Wastewater Treatment Plants: Wastewater treatment plants are common in aeration systems where they provide oxygen to microorganisms that facilitate decomposition of organic matter.

- Power Generation: This is necessary to provide combustion air and cooling uses.

- Cement and Steel Plants: Check air supply to combustion, pneumatic conveying and cooling.

- Food and Beverage Industry: This is used to dry, pack, and keep clean air systems.

- Chemical and Petrochemical Plants: Processes The operations of circulating gas in hazardous conditions are taken care of.

The reasons why Multistage Centrifugal Blowers are better?

The multistage centrifugal blowers are better than the other innovations like positive displacement blowers or single-stage centrifugal units because they have higher performance concerning the stability of pressure, efficiency, and durability. Their history in the critical industries speaks volumes about their worthiness in providing continuity in the systems and energy conservation.

Final Thoughts

Multistage centrifugal blowers are a known solution to industries that require high-pressure, efficient and reliable air movement. Both in wastewater treatment, power plant, and manufacturing processes, these machines provide long term value at a low cost in terms of maintenance. Multistage centrifugal blowers can be trusted by companies who want to be energy efficient and have a consistent performance in order to fulfill their operational requirements.

Having known the advantages and use of multistage centrifugal blowers, the businesses will be in a better position to make informed choices that will improve productivity and minimize its cost. Multistage centrifugal blowers are also worth the cost in case you are planning an upgrade of your air handling systems not only in terms of performance but also in terms of sustainability.