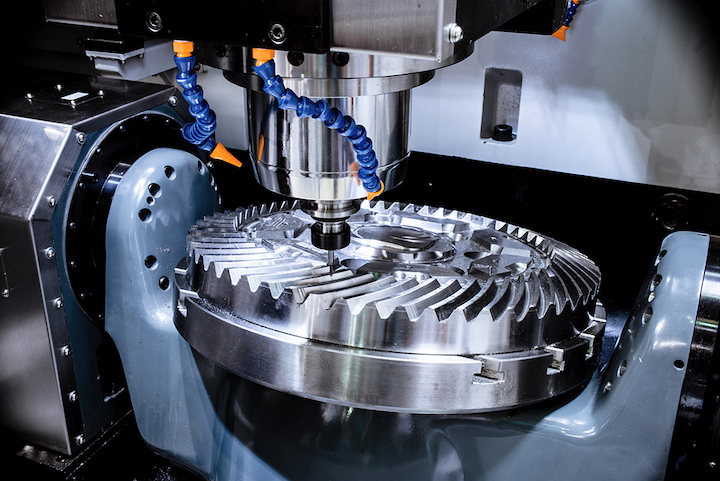

Computer-numerical control (CNC) machining is a manufacturing process used for a range of projects. It is a type of metal fabrication that offers several benefits to businesses in different industries. It is involved in the creation of modern-day devices. It uses CNC to operate machine parts such as grinders, routers, lathes, mills, and shapers. It works without requiring a human operator. Because LOCUS Precision CNC machines are computerised, they offer detailed, consistent results.

How CNC Machines Work

Manufacturers use CNC machining for producing machined parts, items, and products using CNC machines. They are controlled by specialised software with a custom G-Code that ensures features such as speed, feed rate, coordination, and location are precisely controlled.

For manufacturing, CNC machining is useful since the industry requires huge amounts of plastic and metal parts, usually in complex shapes. Different CNC machines provide the benefit of having several axes that can be adapted to hard angles and help manage materials that are not easy to cut.

Basic CNC machines come with a cutting implement together with X- and Y-axes that can work simultaneously and independently. Advanced versions of these machines are available with up to 5 axes that function similarly and can turn and flip a part.

CNC Machining vs Conventional Machining

Both CNC and conventional machining are meant to achieve the same end. They use raw chunks of materials that they shape into a part. CNC machining is an automated process while conventional machining is manual. Compared with traditional machining, CNC is better in terms of speed, accuracy, and production rate. With CNC machining, the software is programmed to cut a part. Meanwhile, with traditional machining, an employee takes the steps for setting up and operating the machine.

Benefits of CNC Machining

CNC machining offers the following benefits:

- Precision components. CNC machining features autonomy and a digital template that eliminate human error and ensures accuracy.

- Dependable endurance. A CNC machine works 24/7 and only stops for necessary repair or maintenance.

- High production rate. After entering the design parameters and specifications into a CNC machine, the latter executes big quantities consistently.

- Increased capability. When a CNC machine is used alongside advanced design software, it can create outputs that no manual machine can replicate. The machine can produce any shape, texture, and size required.

- Product uniformity. CNC machines create products that perfectly match the exact specifications of the prototype. This is something a conventional machine cannot do.